Gas and oil treatment

PEG has more than 20 years worldwide experience making complete Gas & Oil Separation Plants (G.O.S.P.) starting from the Manifolds and including Dehydration and Desalting, Gas Sweetening ang Sulphur Recovery Units

PEG experience includes Crude Distillation Units (Topping), Hydrodesulphurization, Reforming Units and others.

Utilities and offsite facilities

PEG has long experience in the following facilities:

- STEAM GENERATION,

- COMPRESSED AIR,

- WATER TREATMENT,

- HOT OIL,

- TRUCK LOADING,

- PUMPING AND COMPRESSION STATIONS,

- GAS COMPRESSION UNITS

- COMPLETE TANK FARMS.

Transportation Facilities

In the field of Gas Metering and Reducing Systems PEG has more than forty years of worldwide experience, making measurements through the use of well-known methods: orifice fittings, turbines and ultrasonic, in accordance with widely recognized measurement codes such as AGA 3, AGA 7, AGA 9, ISO 5167 and 5168, applied to all pertinent fields, including custody transfer.

In this sector PEG does act not only as a system integrator but has developed its own Supervisory Control System that can be integrated with Kelton validation software for custody application.

A simulator is available in our offices to give clients the opportunity to test and feel confident about the capability of our Supervisory Control System, in a comfortable place.

PEG has developed a fully equipped, wired and tested sheltered control room that can be delivered as a single container ready for field installation anywhere in the world.

PEG is among the few companies able to produce bidirectional or unidirectional Meter Provers, giving clients the possibility to count on a single-source supplier for Metering and Test Prover Systems.

For all components and services not included in its production activity, PEG has acquired a wide experience making it possible to get first class components at the best possible prices, which means that clients are offered top quality metering and pressure reducing stations at excellent commercial conditions.

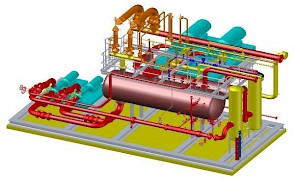

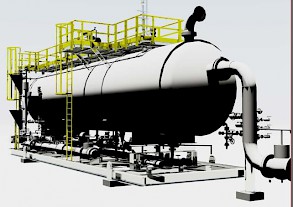

Modularization

Peg has 15 Years of Experience in Modularization in order to provide an economical solution for designing and constructing process plants that are to be built in a resource-limited, hostile or relatively expensive construction environment.

Modularization is the base of our engineering:

- LABOR COSTS OPTIMIZED

- FIELD CONSTRUCTION ACTIVITIES OPTIMIZED AND REDUCED

- PRODUCIBILITY IMPROVEMENT,

- QA AND FABRICATION PROCUDERES

- SAFETY RISK REDUCED

- PEAK WORKLOADS OPTIMIZED, REDUCING DIRECT AND INDIRECT FIELD LABOR.

- IMPROVEMENT ON SCHEDULE

- IMPROVEMENT ON PERMITTING

Revamping

- REVAMPING, THROUGH EXPANSION, UP-GRADING AND CONVERSION

- MODERNIZATION, THROUGH REPLACEMENT, REFURBISHMENT AND CHANGE DESIGN

- DEBOTTLENECKING, THROUGH PLANT PERFORMANCE UPGRADING, COST&BENEFIT OPTIONS

TRAINING

TRAINING: TAILORED TO ALLOW OUR CLIENT TO GIVE THE BEST PERFORMANCES!

PEG is capable to arrange training courses providing trainees with Engineering contracts, helping our stakeholders and us to reach the success in our projects implementation.

OUR TRAINING FACILITIES CREATED TO GIVE THE BEST PERFORMANCES, COMPOSED BY:

- TRAINING ROOMS

- COMPUTER ROOM

- COURSE COORDINATOR ROOM

- AUTOMATIZED OPERATIONAL DESK

- AUDIO SYSTEM

- INTEGRATED WI-FI LESSON SHARING